Ice is at the forefront of a new technology andit’s set to change the way we clean the world.

Coulson Ice Blast technology in an Off-Shore Application

Coulson Ice Blast technology in an Off-Shore Application

Why Use Ice as a Cleaning Media?

Ice is a superior cleaning media

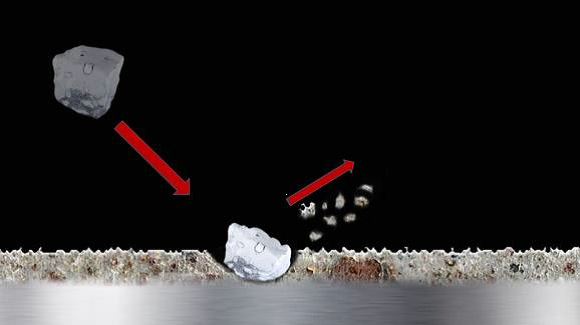

Ice is the only media that exists in all three phases(Solid/Liquid/Gas)

Ice is the only media with three cleaning mechanisms(Bulk removal/Scrubbing/Final Rinse)

冰塊以220M/S高速衝擊清除表面附著物

利用慣性 進行附著物清除

冰塊溶解 清洗表面

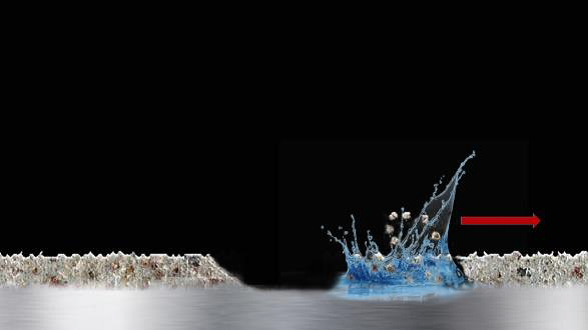

Using Ice produces negligible airborne contaminates(0.003 MG/m3)

Blasting with ice creates very little residual water waste – 95% less water waste than a high pressure power washer.

The Technology

- Simple operational controls(Pneumatic controls optional)

- Non-pressurized 90lb hopper (the IS90 does not hold pressure)

- 110 V/ 240 V electrical plug

- Designed to be intrinsically safe

- Weight:350 lbs

- Compact Design: 40”x26”x45”(LxWxH)

- Operating Pressure:80PSI - 150 PSI、180CFM - 425 CFM

- PSI gauges measuring pressure in and out

- Variable Ice feed rate: 0 – 5 lbs per minute

- Anodized exterior panels

- 36 month or 2000 hr warranty

- Negligible airborne contaminates

Turn Key Ice Making Container

- DNV Certified 10’Container

- 110V/ 240V Electrical Plug for Ice Maker

- Gas generator optional if no external power source available

- Variable size water tanks available

- Ice Production: 2400 pound per 24/4 hour production ice maker

How the IceStorm90 Operates

- Ice cubes are shoveled into the hopper of the machine(top left).

- From the hopper, they fall into a crusher mechanism(top right), which crushes the ice cubes into smaller, rice grain sized particles.

- These particles are then fed from atmospheric pressure into the high pressure airstream through the use of a rotary feeder(bottom left).

- The ice and high pressure air travel through a hose and into a converging-diverging nozzle, through which they are accelerated to high speeds(the air reaches around Mac 2, while the ice exits the nozzle at around 220 m/s) (bottom right)

Ease of Containment

Much of the ice melts on impact and becomes a mist around the work area, making blasted off particulates damp and heavy, dragging them to the ground and leaving low levels of airborne contaminants.

Much of the ice melts on impact and becomes a mist around the work area, making blasted off particulates damp and heavy, dragging them to the ground and leaving low levels of airborne contaminants. Due to minimal water usage and evaporation from impact energy, the only waste left behind is a neat, slushy pile of easily captured contaminant in a tarp placed beneath the blast zone.

Due to minimal water usage and evaporation from impact energy, the only waste left behind is a neat, slushy pile of easily captured contaminant in a tarp placed beneath the blast zone.Before and After Pictures

Before

After

Before